BUILDING A BETTER FUTURE

THROUGH CONVERGENCE

TECHNOLOGY

Lead Tab

Introduction to Lead Tab

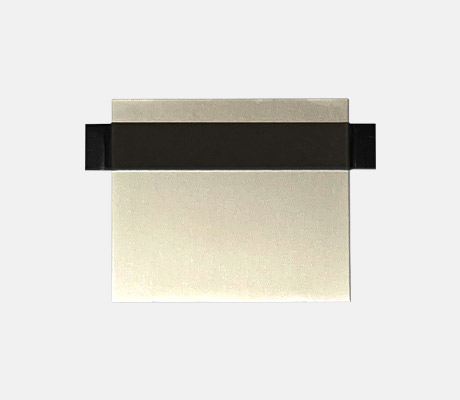

Lead Tab is a component used in

pouch-type batteries and

used in electric vehicle battery cells.

What is Lead Tab?

Lead Tab is the positive and negative terminals of

a pouch-type battery.

As a key component of pouch-type

battery cells, it is a indispensable material that determines

stable power supply and continuous battery life.

-

Anode (Al)

-

Cathode (Ni/Cu)

-

Pouch type secondary battery

Our Technology

Description of Lead tab production process

Description of Lead tab production process

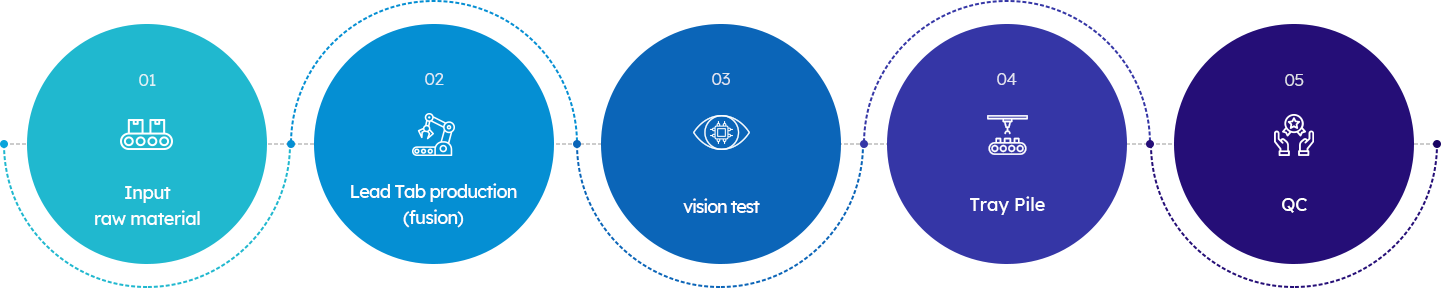

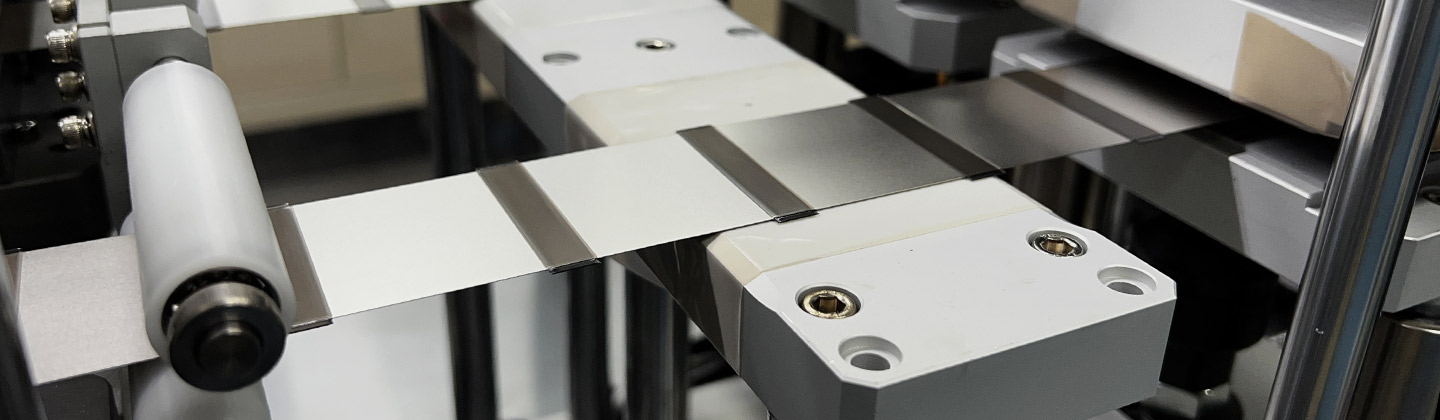

Lead Tab Production Process

Our differentiated lead tab manufacturing technology

introduces and operates state-of-the-art technology for

excellent quality and customer satisfaction.

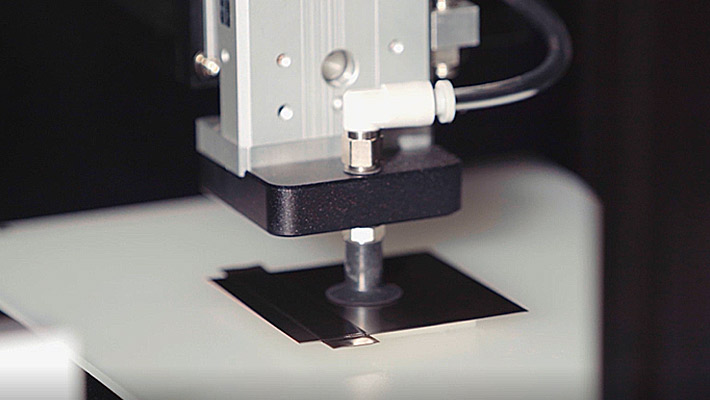

Our technology is divided into 4 processes(Supply Unit,

Fusion Unit, Vision Unit, Load Unit) for attaching the film,

which is the core technology for lead tab production.

A supply unit that sets raw materials to conditions for

fusion of metal and film, which are the core technologies

for lead tab manufacturing.

A fusion Unit does not allow even a small defect of 0.1㎛ to

prevent leakage of the electrolyte of the pouch type

secondary battery.

A Vision part identifies product defects with a

high-performance camera, and a loading part that loads

the finished products into the tray pocket.

Our factory produce world-class lead tabs

through

completed establishment of an automated production

process system

What’s Differentiation of

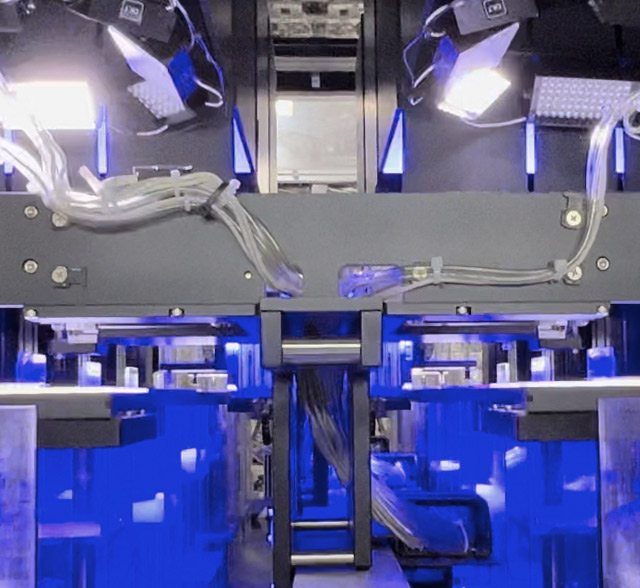

our fusion technology?

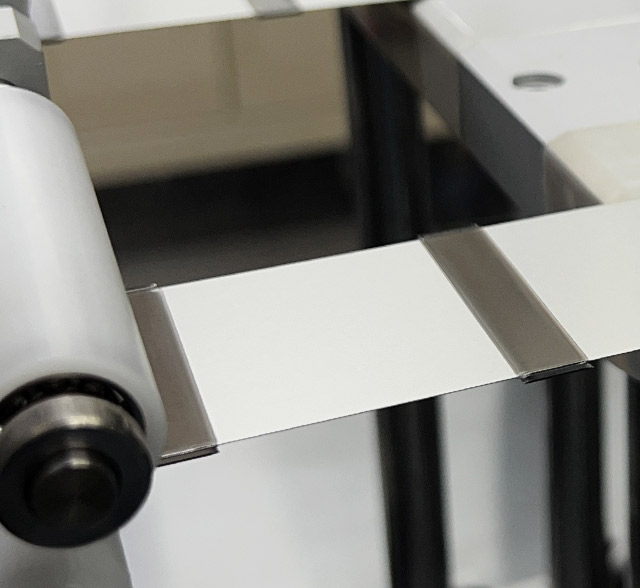

Lead tabs used in pouch-type battery cells must withstand

harsh conditions. A small gap which occurred between the

film and metal leads to electrolyte leakage and a blaze.

In order to protect everyone's safety, our fusion welding

process introduces differentiated technology.

Key of lead tab manufacturing is strong bonding between

raw materials and film. To ensure stable supply of film and

prevent human error, We adopt a self-developed sensor

in each section

of Film passing slot and monitoring the

‘Front and Back classification’ of film in real time.

In addition, in order to prevent fusion defects, we do not

allow even a small fusion defect of 0.1㎛ by ultra-precision

setting with the development of a special mold containing

our know-how.

Our fusion technology is a collection of various equipment,

but it is designed with everyone's safety as the top priority.

‘Interlock’ was introduced in all areas to prevent accidents

that may occur.

Safety of employees is ensured by installing

a 'Safety Cover' to prevent constriction and stab wounds

caused by automated facilities.

The world's best technology and various systems for

everyone's safety are Soulbrain SLD's uniquely differentiated

technologies that have been selected by global companies.